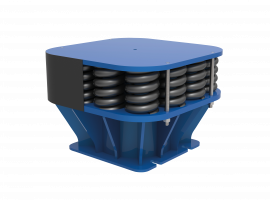

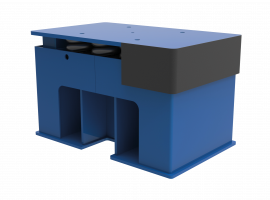

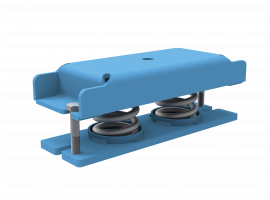

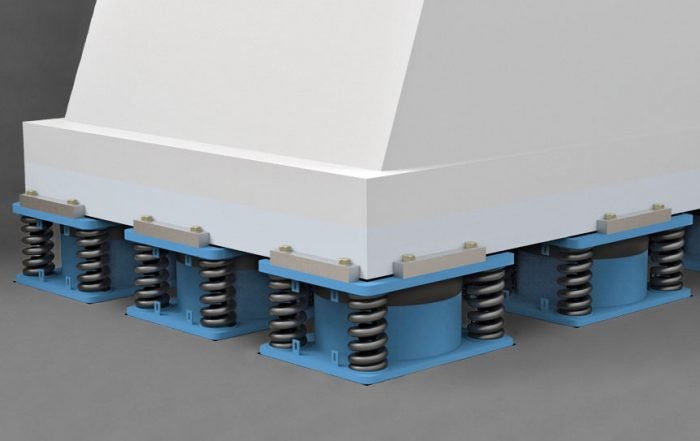

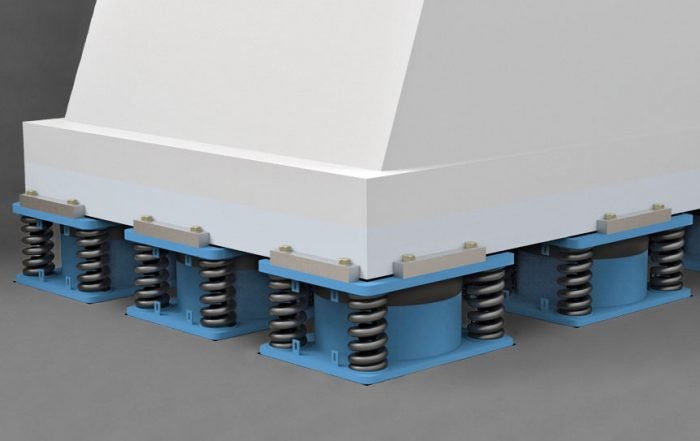

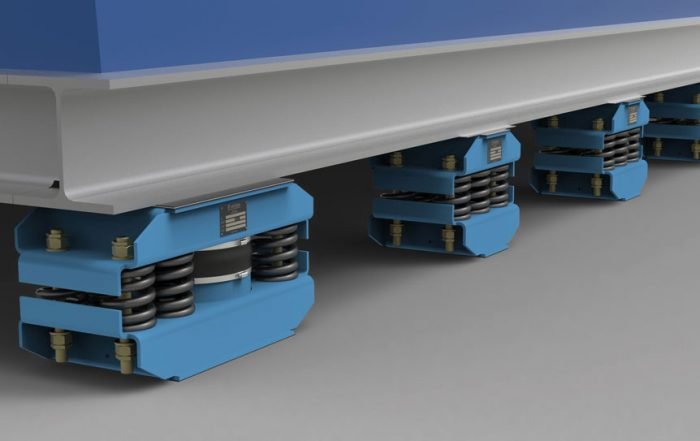

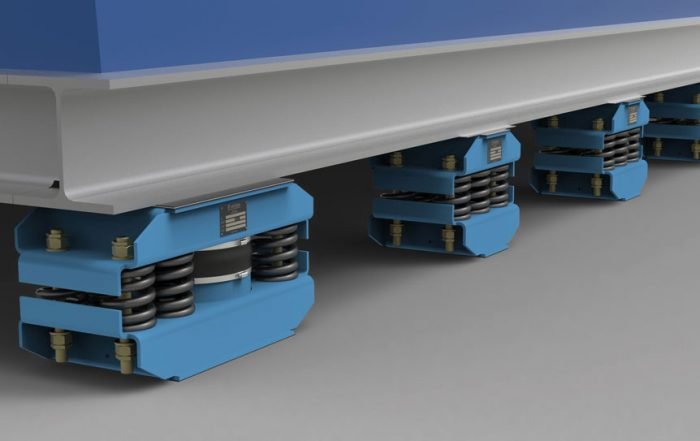

Spring Elements and Spring Damper Elements

There is a variety of specific ranges available for the various applications. These are tailored, manufactured and

delivered according to project requirements. If necessary, the spring elements are equipped with integrated viscoelastic dampers.

- Fields of application

- Operating principle

- Product features

- Type series

- Application examples

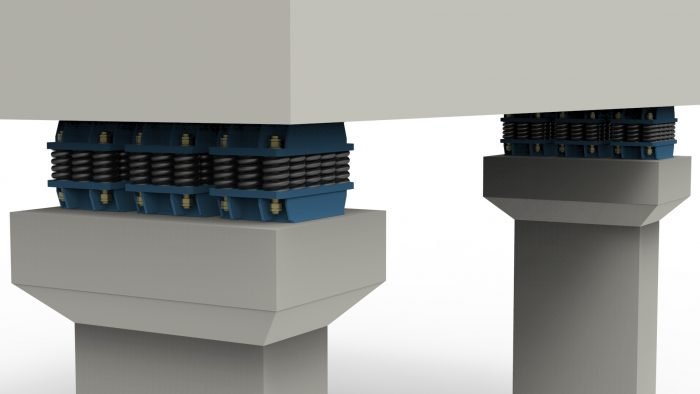

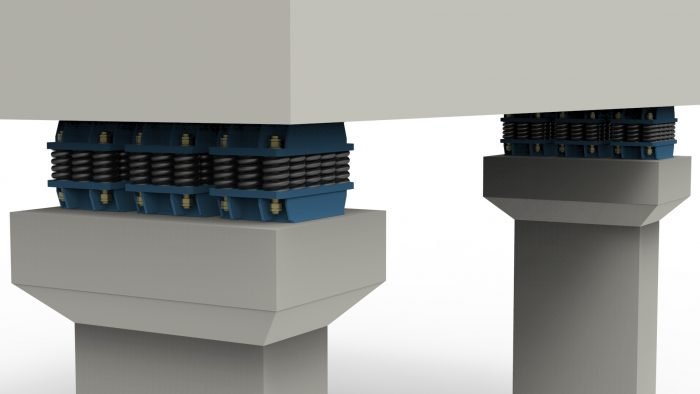

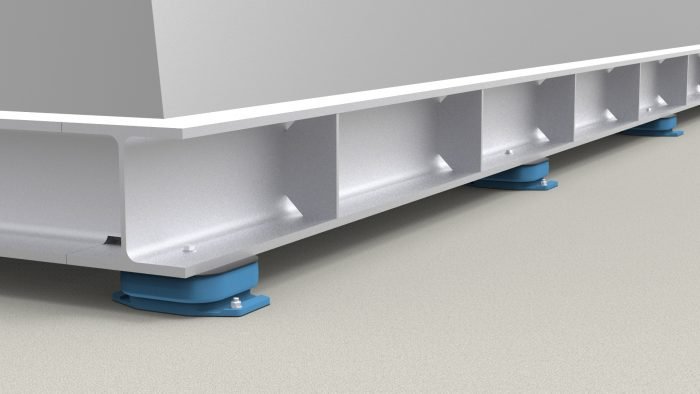

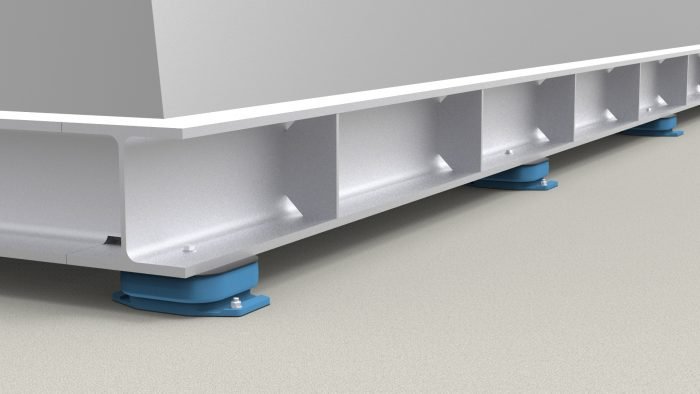

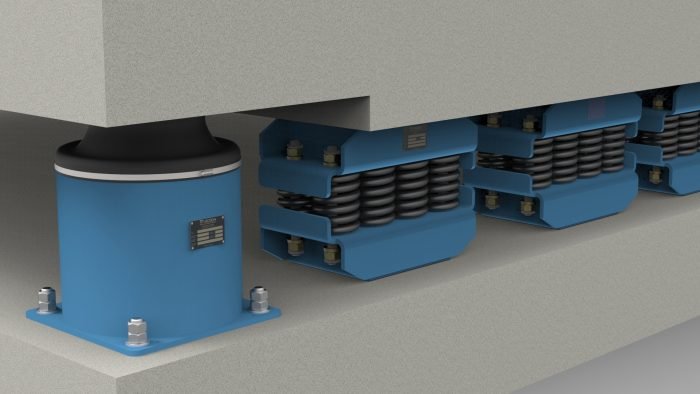

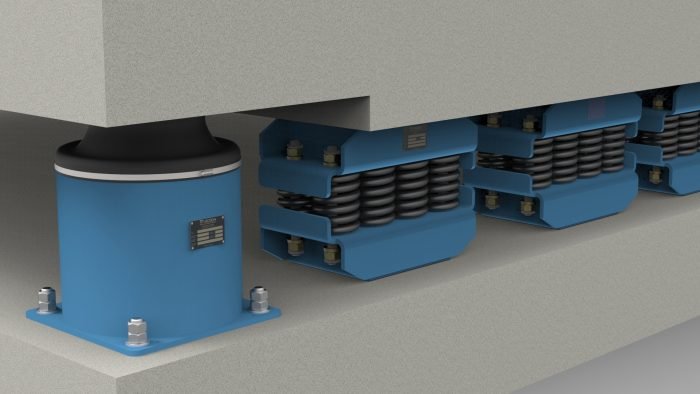

- Mounting examples

- Calenberg Ingenieure

- Fields of application

- Operating principle

- Product features

- Type series

- Application examples

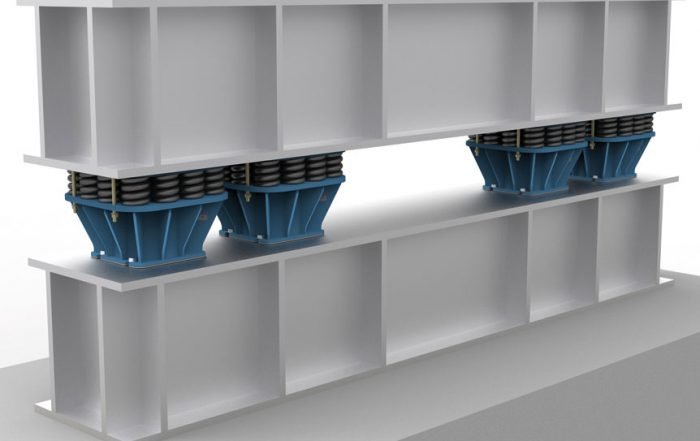

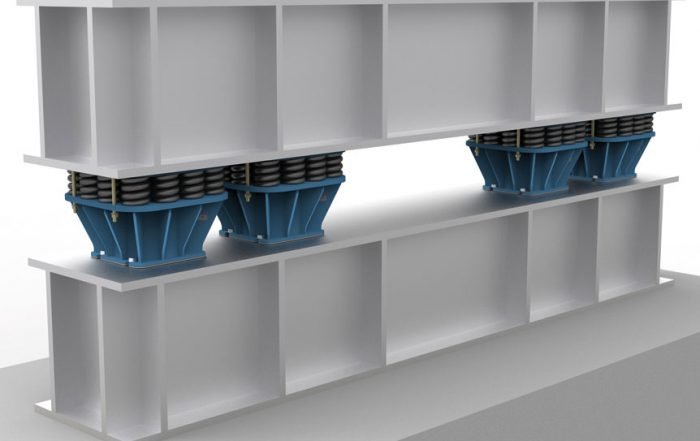

- Mounting examples

- Calenberg Ingenieure

Fields of application

Spring elements are used for applications such as vibration-isolated installation of machinery in power plants, which includes things such as turbines, pumps, blowers, coal mills etc., or of large machines such as presses, forging hammers, crushers and the like. If required, buildings or precision machinery can also be installed with vibration isolation.

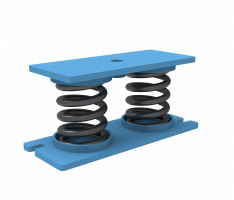

Operating principle

Installing machines with vibration isolation greatly reduces the transmission of dynamic loads between the machine and the foundation. Source insulation reduces the vibrations of crushers or presses, for example. Receiver isolation protects sensitive measuring and production machines from vibrations in the environment.

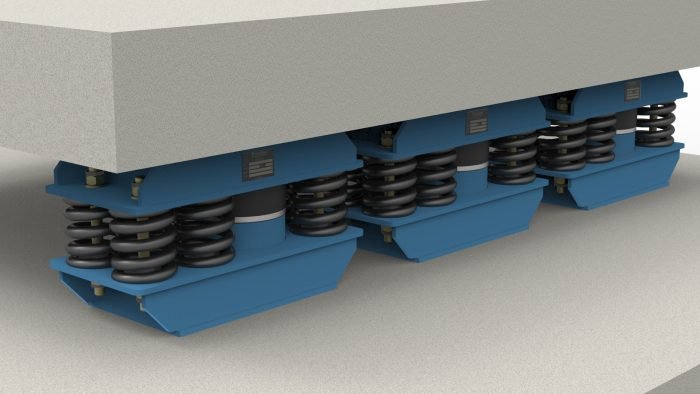

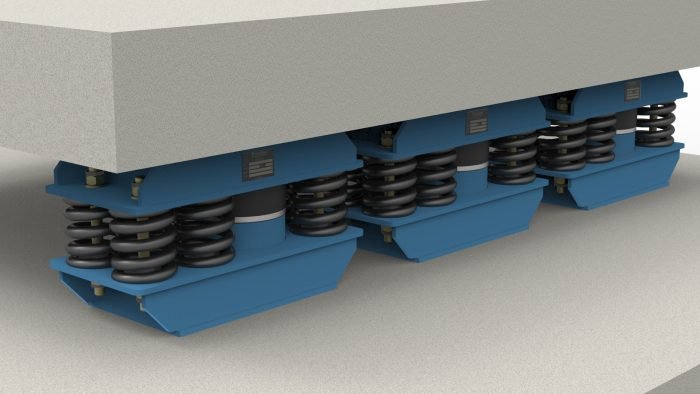

Product features

- Large load range: 1 kN (224.81 lbf) to 2,700 kN (606,984.15 lbf)

- Operational stability compliant with EC 3

- Low natural frequency (1 Hz to 8 Hz) of the system and thus maximum isolation

- Horizontal spring rates of 20% to 130% of the vertical spring rate

- Can be preset and blocked so that a replacement is always available

- Surface coatings for corrosion categories up to C5 compliant with DIN EN ISO 12944

- Individual damping factor with integrated dampers as required

Type series

Application examples:

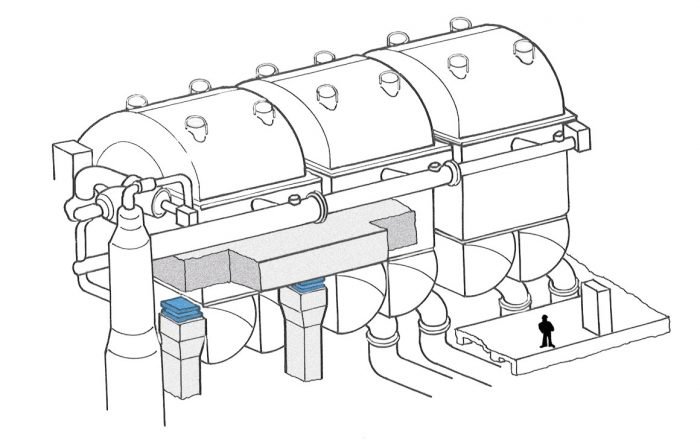

Vibration isolation of industrial machines and plants

Vibration isolation of turbines

The vibration isolated support of turbines has the following advantages:

- Lower dynamic forces affecting the supporting structure and thereby smaller building component cross-sections can be used

- Larger space envelope for the installation of the surrounding capacitors and pipelines

- Easy, elastic compensation of unequal settlements

- Earthquake protection

Vibration isolation of turbines

Vibration isolation of pumps

The vibration isolated support of pumps has the following benefits:

- Vibration reduction

- Easy, elastic compensation of unequal settlements

- Load redistribution

- Earthquake protection

Vibration isolation of pumps

Vibration isolation of fans

The vibration isolated support of fans has the following advantages:

- The possibility of direct bearing

- Reduction of induced dynamic forces into the ground and by that prevention of settlements

- Easy, elastic compensation of unequal settlements

- Easy leveling through shimming

- Defined damping of the fan through extra damping elements

Vibration isolation of fans

Vibration isolation of coal mills

The vibration isolated positioning of coal mills provides:

- Noise and vibration protection for people, plants and surrounding building sections

- Reduced foundation costs

Increased machine reliability and the operating performance - Cost reduction because of reduced machine maintenance and through the prevention of downtime

- Elastic compensation of settlements in operation

- Earthquake protection

Vibration isolation of coal mills

Vibration isolation of forging hammers

With forging hammers the forming energy is mostly imparted by the hammer falling off onto the workpiece. They can be distinguished into drop hammers, double acting hammers and counterblow hammers. With drop hammers the forming energy is the result of the mass of the hammer and the height of fall. Double-acting hammers achieve higher forming energies and impact velocities through an extra acceleration of the hammer.

With counterblow hammers the hammer is paired kinematically or hydraulically with the lower hammer and the impact velocities increase as well. What they all have in common is a primarily vertical shock excitation or shock sequence. Distinctive are the deformation stokes as well as the final rebound impact, with which there is no further deformation of the workpiece and the whole impact energy is transferred to the foundation.

Vibration isolation of forging hammers

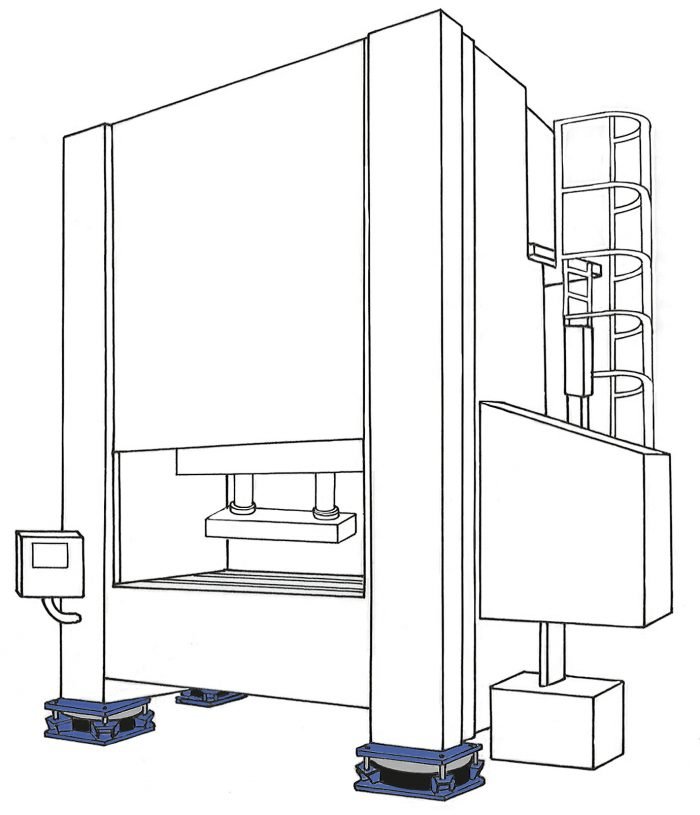

Vibration isolation of forming presses

Forming presses can be divided by the functional principle and the excitation. In hydraulic presses a vertical, impulsive deformation force is provided by the hydraulic medium and the inertia of the ram. With crank, eccentric and screw presses the movement of the ram is given through a gear. The deformation energy is often provided by a flywheel, which is engaged in the deformation process and decelerated through that. In modern servo presses flywheels may partly be dispensed and the ram movement is freely programmable. Superimposed impact force and torque excitations are typical for presses. The resulting vibrations can lead to an overstress of the foundation. In addition to vertical vibrations, tiliting and rotation can also occur.

Vibration isolation of forming presses

Vibration isolation of gas and diesel genarators

Gas and diesel generators are often used as a local energy provider. They consist of an engine and a generator for the power generation, typically positioned on a structural framework. Vibrations occur e.g. through unbalance forces or through a generator short circuit as a fault load condition. Diesel generators are often used for emergency backup in hospitals or in the maritime sector on ships, where high requirements are placed on vibration protection and structureborne sound isolation. For these cases a vibration isolated support is common. Diesel generators are often located in seismic active regions and have to be fully functional after an earthquake.

Vibration isolation of gas and diesel genarators

Vibration isolation of testing machines

Dynamic testing machines like resonance and hydro pulsers or an unbalance exciter are e.g. used for fatigue strength testing of components and can produce large harmonic loads in a predefined frequency. Hydro pulsers can also generate shock type or random exciting forces through the hydraulic control. Vibrations can spread, with a firm foundation, through the subsoil into neighboring buildings.

Vibration isolation of testing machines

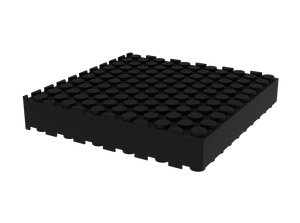

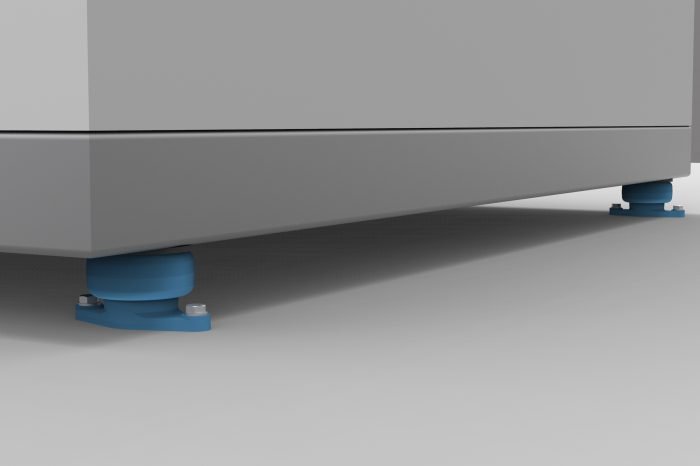

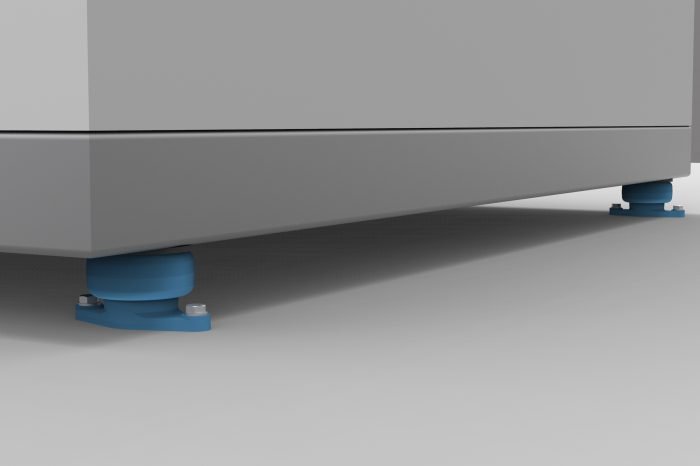

Calenberg Ingenieure:

Vibration isolation of buildings and industrial machinery

For special applications we can also provide vibration isolation with

elastomeric bearings from Calenberg Ingenieure.

For more product information please visit:

LISEGA SE will also be at your disposal, whether for further information or queries.

The products can also be ordered directly from us, if you wish to do.