Viscoelastic dampers

Increased demands on the efficiency, productivity and safety of plants and their pipelines make system reliability more and more important. The dynamic properties of the pipeline system play an important role here.

To control unwanted vibrations within a permissible operating range, viscoelastic dampers, tuned mass dampers and actively controlled dampers are used.

Installation and Operation Manual- Fields of application

- Funktionsprinzip

- Product features

- Type series

- Mounting examples

- Mounting options

- Fields of application

- Funktionsprinzip

- Product features

- Type series

- Mounting examples

- Mounting options

Fields of application

Viscoelastic dampers can be used in almost every industrial sector to reduce resonant vibrations. Applications include energy production, process engineering and damping of individual machines or complete piping systems. Dampers can be used to solve vibration problems as long as a solid bearing of the highest possible rigidity is present. Ambient temperatures of -30 (-22 °F) to + 110 °C (230 °F) as well as extremely demanding environmental conditions (e.g. chemicals, dust or salt-laden atmospheres) are not an obstacle here.

Funktionsprinzip

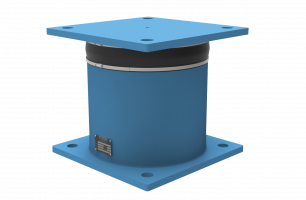

The viscoelastic damper consists of a metal housing filled with a highly viscous medium. A stamp connected to the upper connection plate can move freely in all spatial directions within the medium. Either the upper or lower plate is connected to the vibrating system, while the other one must be mounted on a fixed abutment.

The unwanted system vibrations are converted into heat energy by the movement of the stamp in the viscous medium. This increases the damping, and the resonant “overshoot” is greatly mitigated. Translational as well as rotational degrees of freedom can be damped at the same time. Thermal shifts, such as those in a pipeline, can be taken into account by the deflection of the damper, thus guaranteeing the optimal center position at the operating point.

Product features

- Clamp and damper from a single source

- Effective, simultaneous damping of resonant vibrations in the frequency range 0–35 Hz

- Three different media for different damping and ambient temperature ranges

- Thermal shifts in all directions up to 30, 40, 50 and 70 mm ( 1.18, 1.57, 1.97 and 2.76‘‘) possible

- Fail-safe technology with high damping performance

- Sophisticated coating requirements are possible, e.g. offshore standard C5-M/H

- Thermal decoupling possible through the use of insulator plates (cryogenic and high-temperature application)

- Also available in duplex steel

- Development and production of the adjacent construction (mounting and secondary steel construction)