Dynamic components

The absorption and transfer of dynamic loads requires specially designed supports. Product group 3 provides a complete product portfolio that covers all fields of application with the ideal component.

Download product catalog (metric)- Application

- Mode of operation

- Scope of performance

- LISEGA Benefits

- Designs

- Connections

- Mounting examples

- Products:

- Application

- Mode of operation

- Scope of performance

- LISEGA Benefits

- Designs

- Connections

- Mounting examples

- Products

Application

The use of snubbers is preferred in thermally operated plant components. In a dynamic event, snubbers instantaneously provide a fixed, practically rigid connection between the component to be secured and the surrounding structure. In this way the dynamic energy from abrupt displacement can be absorbed at once and harmlessly dissipated. The thermal displacements during routine operation remain free of any significant resistance thanks to the specialised operating principles of the snubbers.

Mode of operation

The function of LISEGA hydraulic snubbers type 30 is controlled by a main control valve positioned axially in the hydraulic piston. On slow movement of the piston, the valve is held open by spring force and the hydraulic fluid can flow freely from one cylinder chamber into the other. On rapid piston movement above a velocity limit, back pressure develops on the valve disk and closes the valve. The hydraulic flow is interrupted and the movement blocked.

The operational mode of LISEGA hydraulic snubbers type 31 is in principle based on the same concept as of type 30. The particularities of size require a different arrangement of the compensating reservoir. At the same time, a different arrangement of the valves is also necessary.

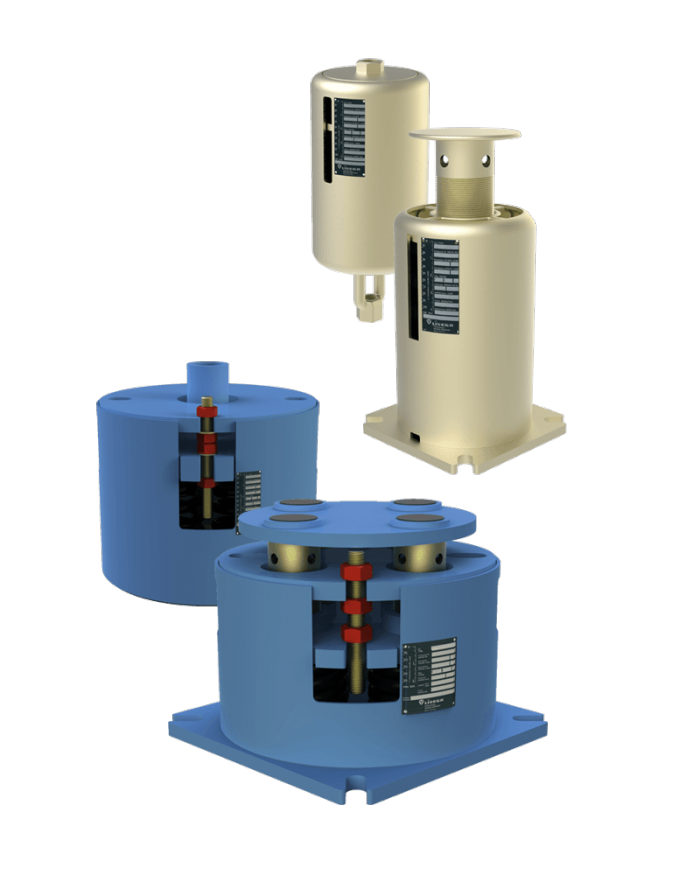

Scope of performance

Load

3 kN to 5,000 kN / 674.43 lbf to 1,124,044.72 lbf

Stroke

100 to 750 mm / 3.94 to 29.53 in

LISEGA Benefits

LISEGA snubbers are characterised by superior functionality and durability due to:

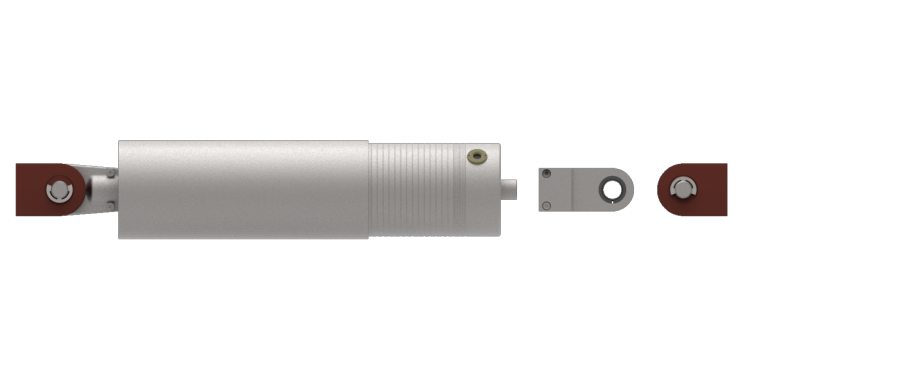

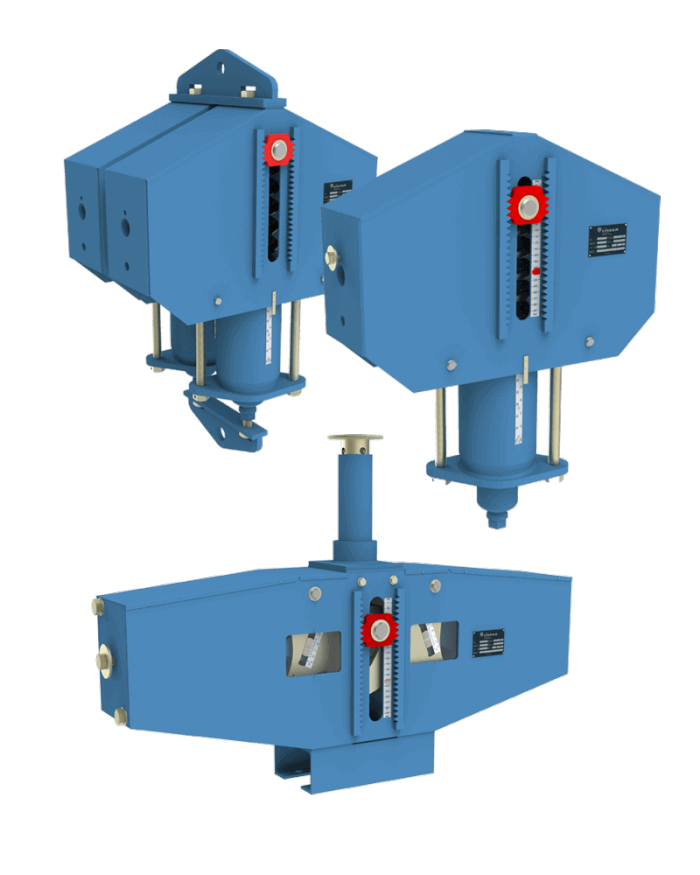

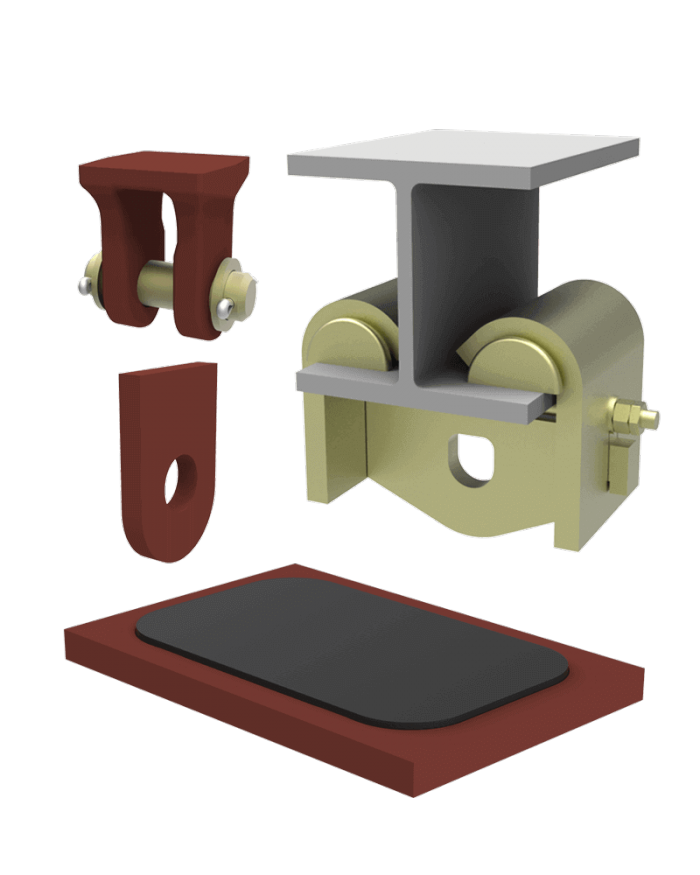

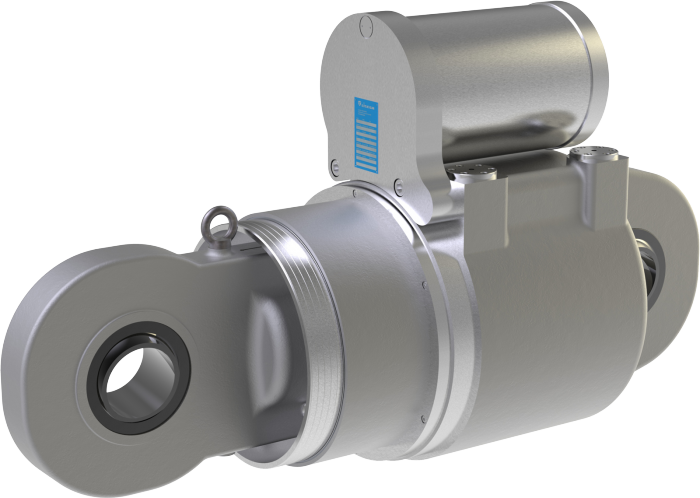

- Type 30

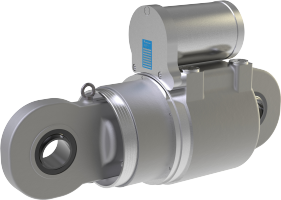

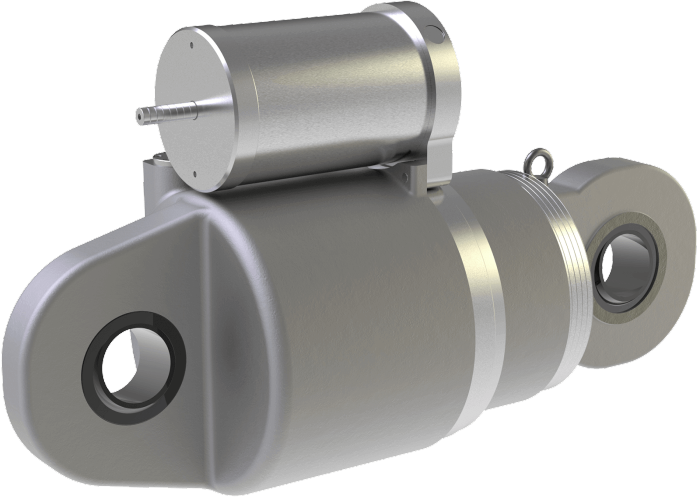

- Type 31 front view

- Type 31 rear view

Name plate with all relevant technical data

Indicator for fluid level

Indicator for piston position

Compensating reservoir

Connecting lugs

Compensating reservoir

Name plate with all relevant technical data

Control valves to achieve high operating precision

Indicator for piston position

Indicator bar for fluid level

- Corrosion-resistant materials

- Radiation-resistant and wear-resistant sealing systems

- Vibration-resistant guides

- Pressurised hydraulic system for optimal sealing

- Dynamic functional behaviour

- Tested and approved for minimum 23 years maintenance-free operation

- Lifespan of 60 years

- Certified by suitability tests acc. to KTA 3205.3 and approvals acc. to ASME-NCA 3800

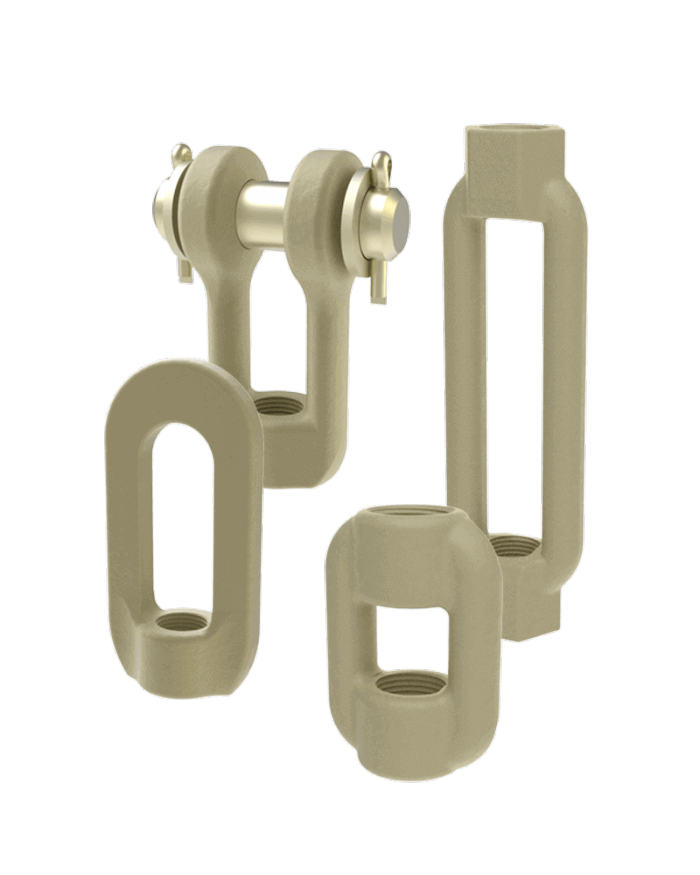

Connections

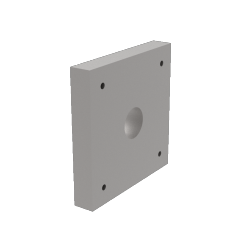

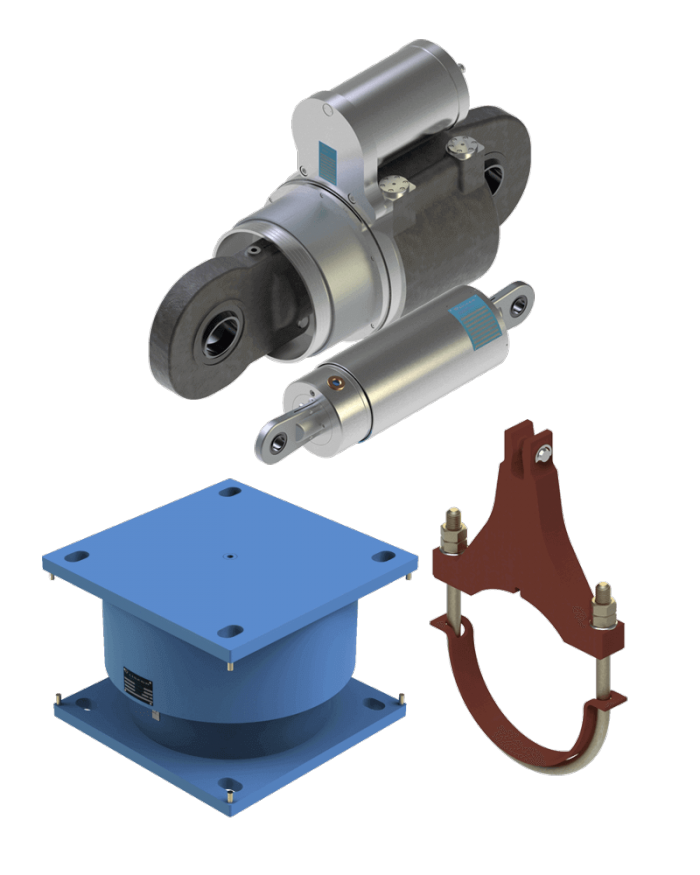

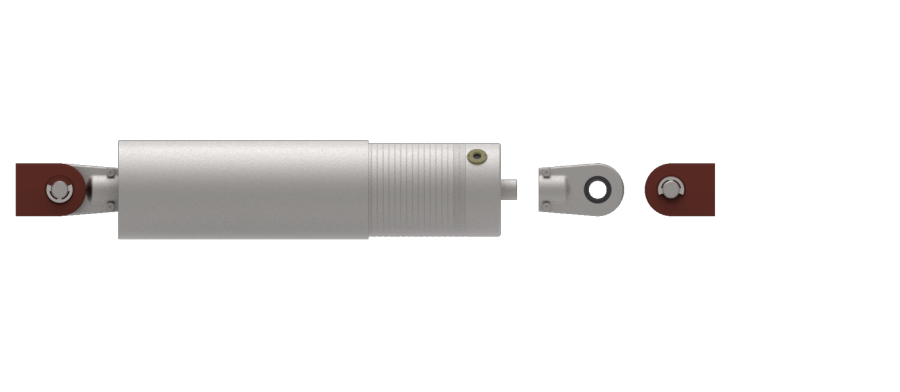

Weld-on bracket type 35

CloseWeld-on bracket type 35

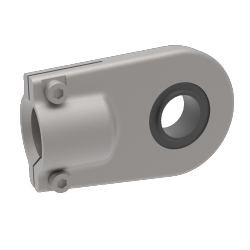

CloseConnecting lug

Close

Weld-on bracket type 35

CloseWeld-on bracket type 35

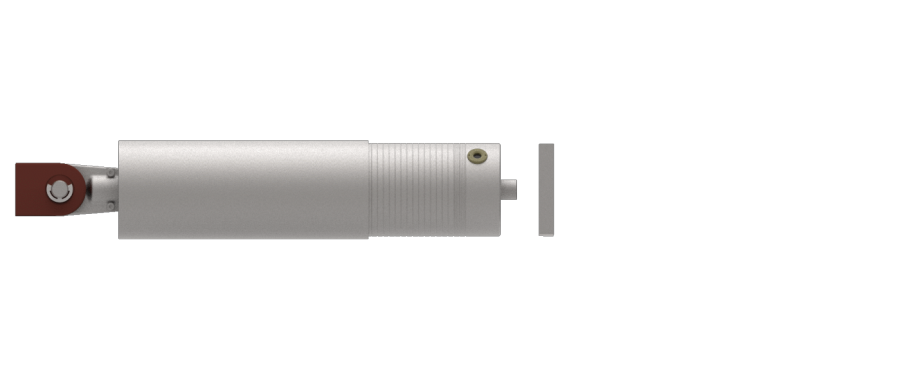

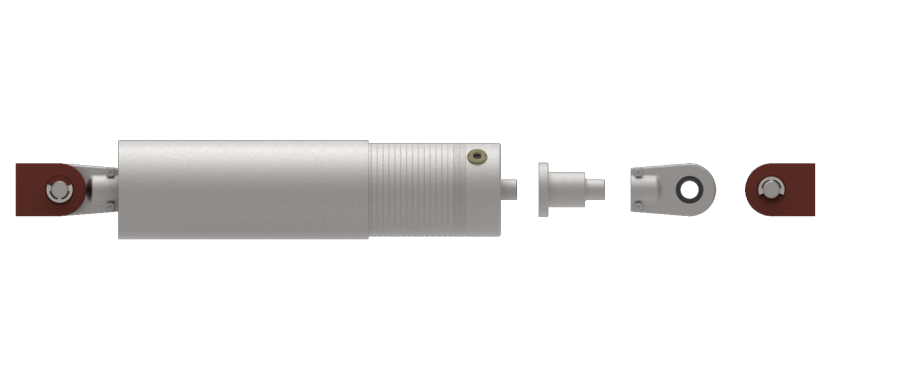

CloseInstallation extension type 33 with length adjustment

Close

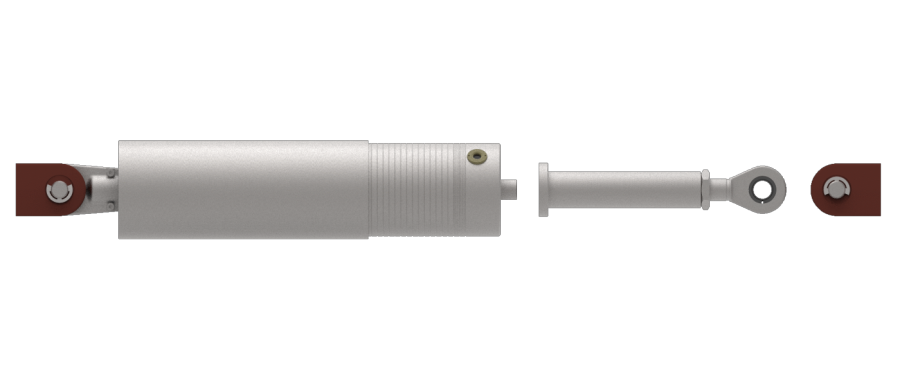

Weld-on bracket type 35

CloseFlange for connection to existing extensions

Close

Weld-on bracket type 35

CloseWeld-on bracket type 35

CloseShort extension without length adjustment

CloseConnecting lug

Close

Weld-on bracket type 35

CloseWeld-on bracket type 35

CloseSpecial lug

Close